Basic Info.

Model NO.

Silent Type - SP1000

Certification

CE, ISO9001: 2000

Condition

New

Operating Weight

1007 Kg

Required Oil Flow

80-110 Liter/Min

Diameter of Hose

19.05 mm

Tool Diameter

100 mm

Impact Energy

2100 Joule

Noise Level

91 Lpa

Origin

Shanghai

Production Capacity

2000pieces/Year

Product Description

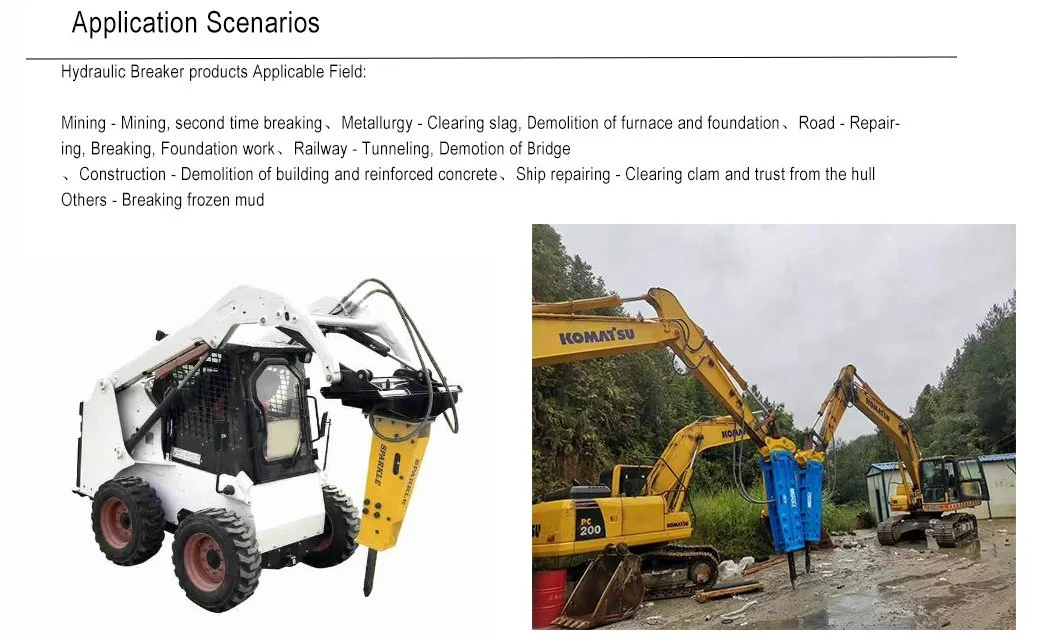

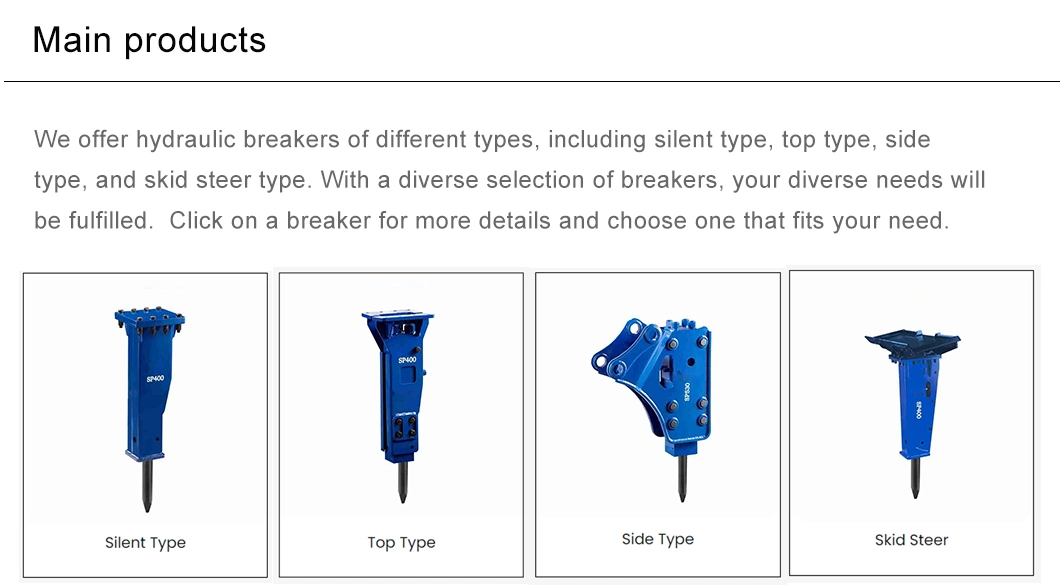

excavator breaker hydraulic hammer rock breaker hammer jack hammer for loader

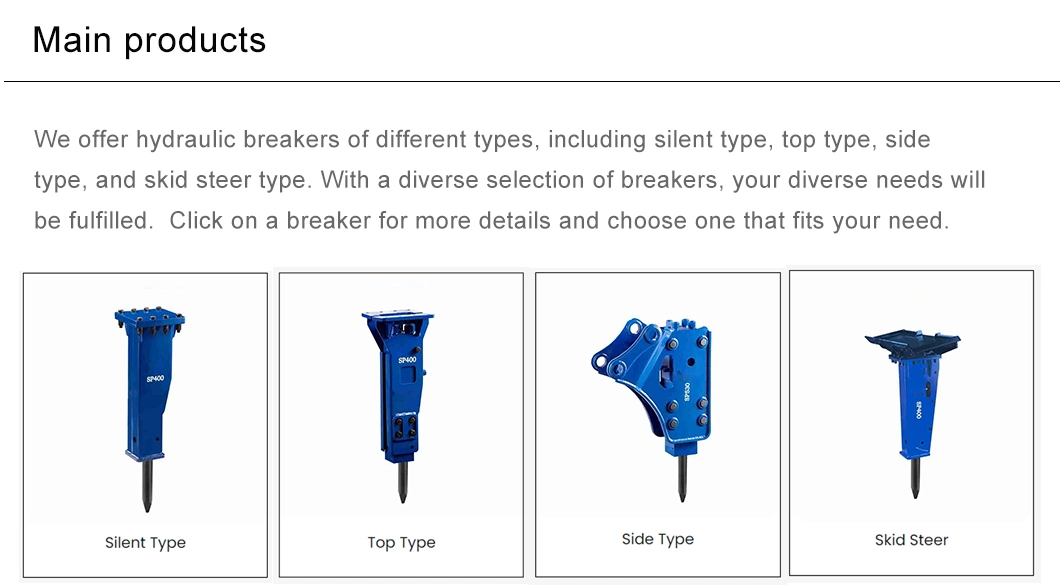

Silent Type Hydraulic Breaker

Main Features:

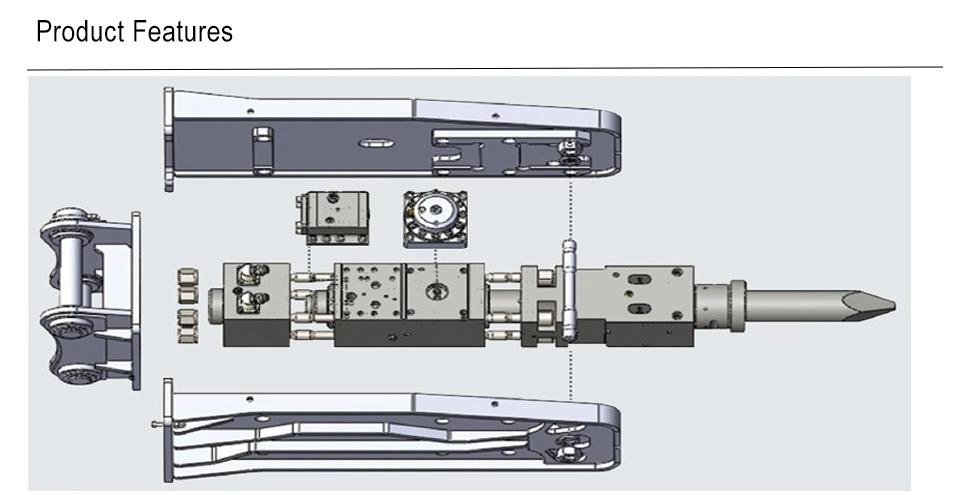

1.Direct Manufacture factory.

All Hydraulic Breakers and Spare parts are designed, manufactured and assembled byProduct Quality is guaranteed,can be used for a long working life without defects.Spare parts supply system is steady.

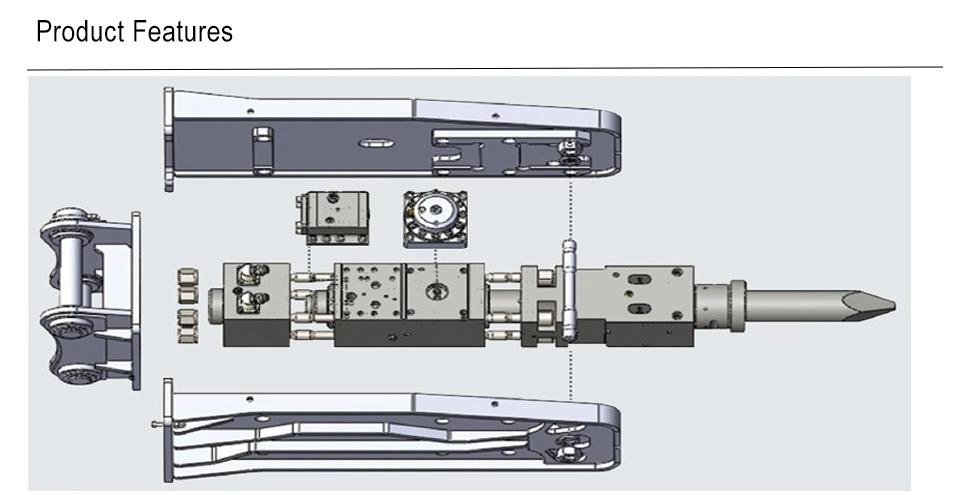

2.High Strenath and wear resistance steel plate adoptedThe bottom of hydraulic breaker adopted high strength and wear resistance steel plate, which not only guarantees the long life ofbreakers, but also enhances the working efficiency

3. Latest heat treatment technologyPiston, cylinder, front part of the main body, and other main parts of the gear are all treated by lastest heat treatmnet equip-ments. Years of technical heat treatment experience has ensure the quality and stability of our Sparkle product, making us theleading role in the production of broken hammer.

4.Efficient work efficiency & unique valve systemSparkle hydraulic breakers adopt unigue hydraulic circuit, requiring less oil, which greatly improve the efficiency of power gener-ation

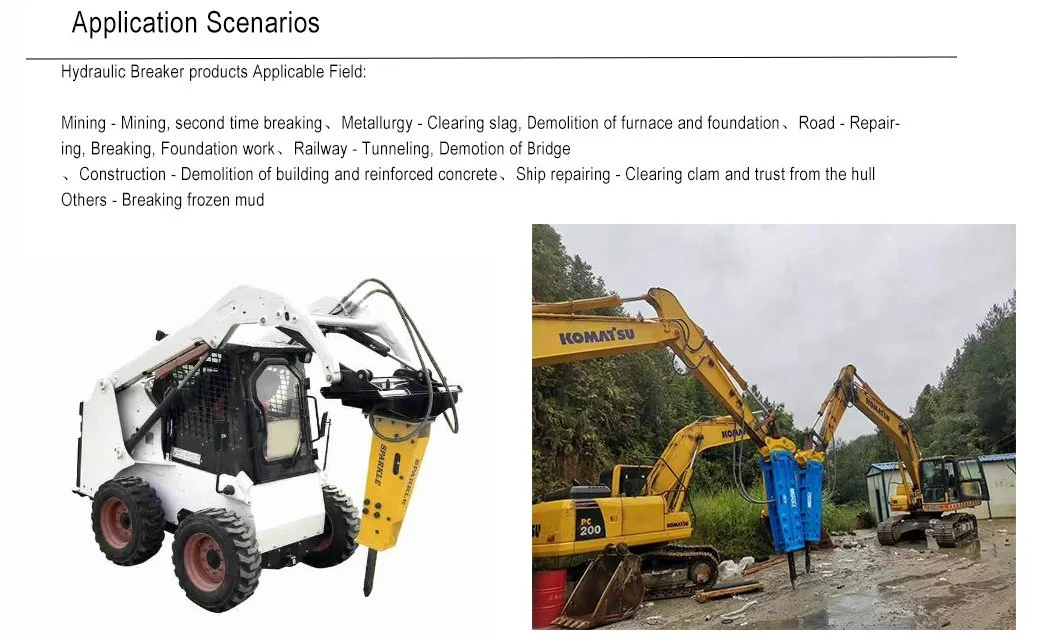

5. Strong compatibility.

Sparkle hydraulic breakers are compatible with all kinds of excavators such as Doosan, Dawoo, Volvo, Hitachi, Kato, Kobelco., Sumitao, Liebheer,Hyundai, Jonyong, Changjiang, Liugong, Yucai, Case, John Deer, Fotonlovol and Loader etc

6.Strict quality control system:

A professional QC team and advanced machinery to ensure the quality of Sparkle products

Silent Type Hydraulic Breaker

| Model | SP400 | SP450 | SP530 | SP680 | SP750 | SP850 | SP1000 | |

| Specs | Value | Unit | ||||||

| Suitable Excavator Weight | 0.8-2.5 | 1.2-3.0 | 2.5 - 4.5 | 4.0 - 7.0 | 6.0 - 9.0 | 7.0-14.0 | 10.0-15.0 | ton |

| 1764-5512 | 2646-6614 | 5512-9921 | 8818-15432 | 13228-19842 | 15432-30865 | 22046-33069 | lb | |

| Operating Weight | 102 | 129 | 155 | 361 | 450 | 733 | 1007 | kg |

| 225 | 284 | 342 | 796 | 992 | 1616 | 2220 | lb | |

| Impact Rate | 800-1300 | 700-1200 | 600-1000 | 500-900 | 450-800 | 400-800 | 350-700 | bpm |

| Operating Pressure (Breaker) | 90-120 | 90-120 | 90-120 | 110-140 | 120-150 | 130-160 | 150-170 | kg/cm2 |

| 1280-1700 | 1280-1700 | 1280-1700 | 1562-1988 | 1704-2130 | 1846-2272 | 2130-2414 | psi | |

| 88-117 | 88-117 | 88-117 | 108-137 | 118-147 | 128-157 | 147-166 | bar | |

| Setting Pressure (Machine) | 130 | 130 | 150 | 160 | 160 | 180 | 200 | bar |

| 1846 | 1846 | 2130 | 2272 | 2272 | 2556 | 2840 | psi | |

| Back Head Pressure | 12 | 12 | 16 | 16 | 16 | 16 | 16 | bar |

| 170 | 170 | 227 | 227 | 227 | 227 | 227 | psi | |

| Accumulator Pressure | NA | ZD | NA | NA | NA | NA | NA | bar |

| NA | ZD | NA | NA | NA | NA | NA | psi | |

| Required Oil Flow | 15-25 | 20 - 40 | 25-50 | 40-70 | 50-90 | 60-100 | 80-110 | liter/min |

| Diameter Of Hose | 12.7 | 12.7 | 12.7 | 12.7 | 12.7 | 19.05 | 19.05 | mm |

| 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.75 | 0.75 | inch | |

| Tool Diameter | 40 | 45 | 53 | 68 | 75 | 85 | 100 | mm |

| 1.57 | 1.8 | 2.1 | 2.7 | 2.9 | 3.3 | 3.9 | inch | |

| 4 | 8 | 9 | 18 | 23 | 31 | 57 | kg | |

| Impact Energy | 230 | 290 | 320 | 690 | 900 | 958 | 2100 | joule |

| 170 | 213 | 236 | 509 | 663 | 958 | 1549 | ft-lb | |

| Noise Level | 85 | 86 | 87 | 88 | 88 | 89 | 91 | LPA |

| 113 | 114 | 115 | 116 | 116 | 117 | 119 | LWA | |

Main Features:

1.Direct Manufacture factory.

All Hydraulic Breakers and Spare parts are designed, manufactured and assembled byProduct Quality is guaranteed,can be used for a long working life without defects.Spare parts supply system is steady.

2.High Strenath and wear resistance steel plate adoptedThe bottom of hydraulic breaker adopted high strength and wear resistance steel plate, which not only guarantees the long life ofbreakers, but also enhances the working efficiency

3. Latest heat treatment technologyPiston, cylinder, front part of the main body, and other main parts of the gear are all treated by lastest heat treatmnet equip-ments. Years of technical heat treatment experience has ensure the quality and stability of our Sparkle product, making us theleading role in the production of broken hammer.

4.Efficient work efficiency & unique valve systemSparkle hydraulic breakers adopt unigue hydraulic circuit, requiring less oil, which greatly improve the efficiency of power gener-ation

5. Strong compatibility.

Sparkle hydraulic breakers are compatible with all kinds of excavators such as Doosan, Dawoo, Volvo, Hitachi, Kato, Kobelco., Sumitao, Liebheer,Hyundai, Jonyong, Changjiang, Liugong, Yucai, Case, John Deer, Fotonlovol and Loader etc

6.Strict quality control system:

A professional QC team and advanced machinery to ensure the quality of Sparkle products